Pharma Tanks, Vessels for Pharmaceutical Applications

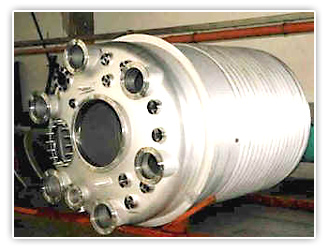

Pressurized and non-pressurized storage or process vessels with special requirements to the optical appearance and the technical processing are used particularly in the pharmaceutical industry.

These tanks require an optimal exterior appearance, easy to maintain surfaces, and a roughness depth with Ra-value below 0,3µ on the contact surfaces of the processed product. These requirements are standard of the grinding and polishing technique with Technnique Engineering Services Concern.

The manufacturing spectrum reaches from small mobile tanks with working capacities starting at 10 liters up to large volume process or storage tanks.

Process Tanks, Process Vessels, Process Apparatus

Pressurized and non- pressurized tanks or vacuum vessels are utilized to process products according to customer specifications. The client carries hereby the responsibility for the process engineering and for the operational conditions and sequences.

The technical implementation takes place by the external and internal installation of components such as mixing units, heating or cooling, in combination with biological and chemical operational sequences.

As for any product category, the Technnique Engineering Services Concern group manufactures custom-made apparatus complying with the specific customer requirements and in accordance with the current regulations.

For high-precision sealing surfaces and construction intersections of complex apparatus, Technnique Engineering Services Concern contracts a precision tooling company adjacent to the Technnique Engineering Services Concern premises.