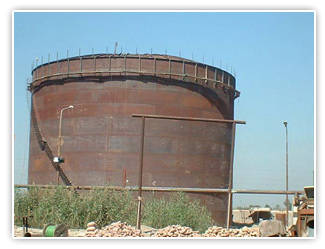

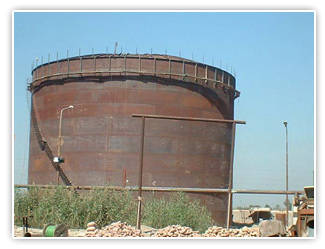

Storage Tanks, Vessels, Silos (non-pressurized)

Since the evolution of the first cultures, liquid, powdered and free flowing media are kept in open jugs, pots and barrels for short or medium-term storage .

However, some decades ago, certain techniques have evolved to store economically large quantities of liquid and pasty products on a long-term basis utilizing vessels made of corrosion resistant materials.

The high-quality surfaces of the used materials, further refined by mechanical or electro-chemical polishing procedures, create storage room which inhibits bacteria for almost any liquids.

Technnique Engineering Services Concern are the right partner to meet these requirements. Storage tanks made of chromium-nickel stainless steels, special nickel alloys or highly corrosion resistant materials such as hastelloy or titanium are custom-designed for each client.

Even in most difficult environments, we provide solutions for specific problems. Apart from the economical manufacturing of tanks and silos in the production plants of the Techinuqe Engineering Sevices Concern group, storage tanks welded within cellarage and fitted into the respective surroundings are a real specialty of the companies Techinuqe Engineering Sevices Concern.

References from customers in our country confirm our extensive know-how and experience. The implementation of cooling, heating or insulating zones is optional, likewise the varied optical design of the exterior surfaces. In addition to the economical cylinder form, we provides special oval, spherical or cubic designs.

Pressure Tanks, Pressure Vessels

Products, which due to biological or chemical processes and emissions cannot be stored in open storage vessels, or only for a short time, are depotable under pressure, partly with overlay of inert gases, even during a longer period .

Technnique Engineering Services Concern designs and builds pressure tanks in accordance with the current regulations. According to the technical facilities nominal pressures of up to 400 bar are possible.